1. The first is that the relevant production enterprise formulates or selects coding rules, generates a certain number of two-dimensional codes, and forms a complete database system.

2. Send the produced database system to the relevant enterprise responsible for producing the packaging.

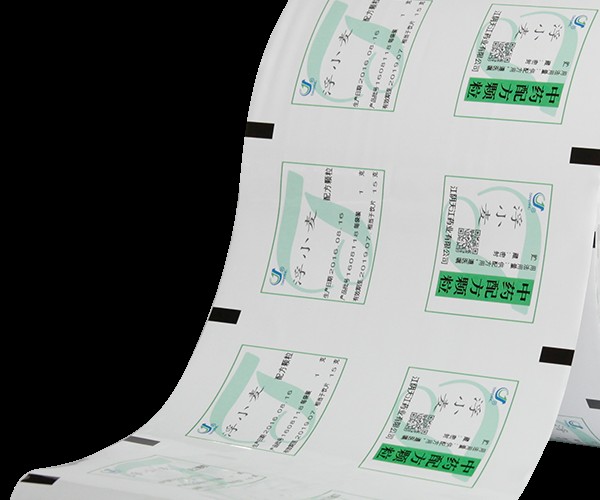

3. The packaging company receives the data to organize and dock. Then send it to the marking equipment such as printer, laser printer or high-resolution printer to print the product. Realize what we often say “one thing one code”.

4. Combining the custom packaging bag that has been coded and not coded. Establishing multi-level related packaging relationship, such as bag-inner box-outer box. The association relationship of the two-dimensional code can be customized according to customers’ needs. It strengthens the control of product quality.

5. When the products leave the warehouse, clearly mark the production place and sales area of each batch products. We can analyze the flow of products combined with dealer logistics data, which can effectively maintain the healthy development of the market.

6. Consumers can inquire about the authenticity of each product and related information such as production date, place of origin, batch number and so on from the custom packaging bag. And this information can be shared through mobile phones.

7. According to the customer’s barcode scanning situation, after the data is uploaded, there will be a big data analysis system, which allows the enterprise to have a deeper understanding of the product market dynamics.

It is recommended that customers can choose a coding platform for auxiliary processing and coding. Each product is given a different, random, encrypted and bound unique identity code to realize one thing one code. At the same time, two-dimensional code spray code detection system can be installed on each production line. With the detection and rejection device, it can ensure high-quality product coding. The three-dimensional code spraying code detection system generates codes online and performs high-speed instant coding at a certain speed online in real time. Ensure that there are no missing codes/heavy codes/residual codes, and the mobile phone application can be 100% readable and can be associated with product cans/bottles/boxes. Collect consumption data and establish a brand marketing database. Realize the goals of QR code marketing, consumption analysis, and product flow query through big data analysis.