The future development direction of digital printing(bright future)

To describe the prospects of digital printing in one sentence: the general trend, whoever is better. After more than ten years of hard work, digital printers can finally say this boldly today.

In Europe and America, the digital printing industry is very developed, and orders of less than 5000 copies are basically occupied by digital printing. Many large printing houses have more than 10 digital printing presses. Among them, 30% of digital printers serve for network personalized printing. Online personalized prints are mainly photo books and personalized desk calendars. They are very keen on this kind of personalized prints. For example, Prince William’s wedding has a lot of personalized prints, among which the beer labels are digitally printed.

In China, labor costs are increasing. Compared with traditional printing, digital printing, which requires less labor, saves a lot of labor costs. Part of the traditional printing business is shifting to digital printing. After several years of development, network personalized printing has become more mature, which has also promoted the development of digital printing.

From 2001 to 2010, my country imported a total of 26,710 digital printing presses. In 2007, 1,164 units, with a total value of 38.92 million yuan; in 2008, 1161 units, with a total value of 29.47 million U.S. dollars, a decrease of 24.3%; (calculated by amount) in 2009, 6,987 units, with a total value of 55.22 million U.S. dollars, an increase of 87.4%; in 2010, 17,398 units, with a total value of 86.12 million U.S. dollars, an increase of 55.6%. The majority of digital printing companies work together to meet a better tomorrow and make digital printing bigger and stronger.

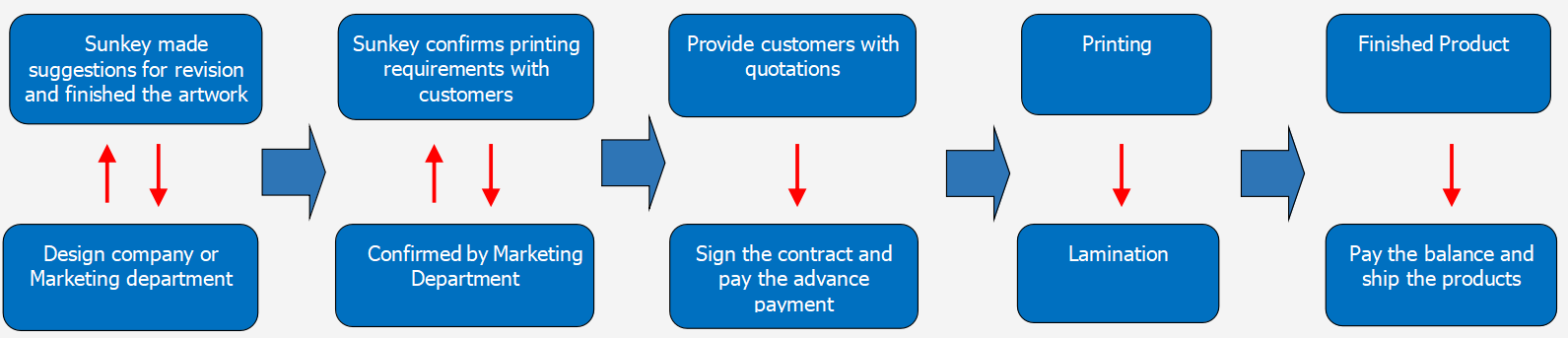

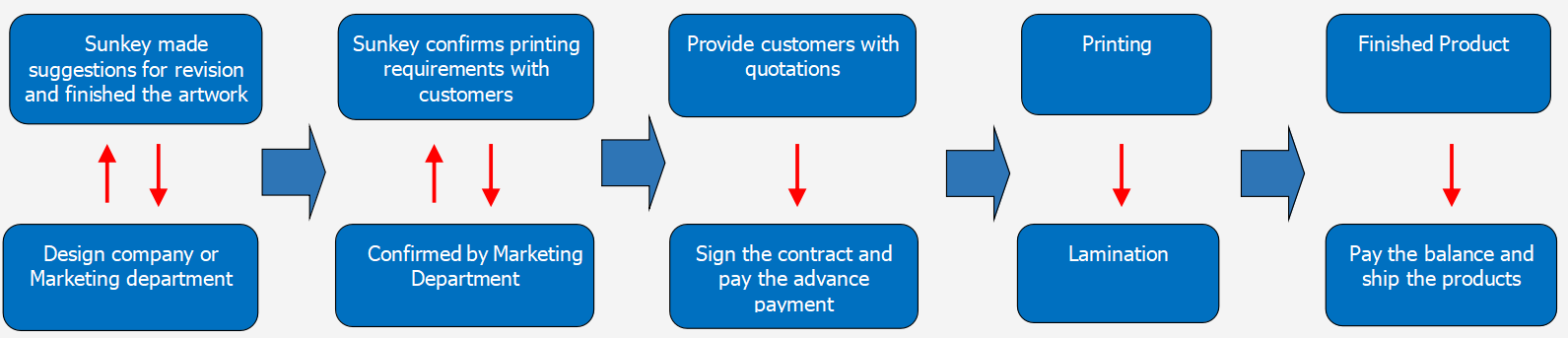

Sunkey Digital Printing Operation Sequence